THE ABC OF THE GAS CONDENSING BOILERS

According our opinion the most important indicators to select a condensing boiler are:

a) THE WEIGHT. The boilers produced with nobles materials like brass, stainless steel, copper weigh around 40 kg (model of 25 KW). The boilers made with poor material like plastic, weigh much less..(about 30 kg).

b) THE ORIGIN. It is not enough the brand of the product, it is a good habit, check where it is produced..(the “Made in…”). Often, behind blazoned brands (also German) there are products coming from China or Turkey, addressed to the first price market.

c) THE PRICE OF THE SPARE PARTS. A company who operates with transparency has no difficulties to publish the prices of its spare parts on its website. It is important check that the spare parts are not “special”, that’s to say that can be find in the market easily by the customer and overall that He is not forced to buy them only from the manufacturer, because the consequences on the prices could be heavy..

d) the COMMUNICATION. If communication relies on emotional aspects, draws the customer's attention on aspects entirely unrelated to the product, if it uses images of children or smiling models while are having a shower or if it is emphasized the image of the happy family, the dream house with beautiful furniture, you have to be wary: it is very likely that the purpose is distract the customer. In other words, subtly, communication makes lever on the customer’s unconscious, using images that have nothing to do with products. A "honest" company does not need to exploit the positive image of children who are playing with a boiler. A “honest” Company focuses on the quality of their product ......if it has it.

Finally, buy a boiler of some famous brand at a cheaper price, could reveal itself an unhappy choice, after finding out that the boiler has been assembled in Far or Middle East with poor quality components sometimes dedicated to that particular model (with spare parts sold at prices 3 times higher than the standard ones)

To sum up, with the 4 points here above mentioned we can speak of a planned obsolescence product.

Why we have not yet spoken about emissions and commissions?

Because with the new standards ERP we have just with two letters, all the boilers are in A class or B class with a difference of consumption that keeps below the 2%, so it cannot affect the customer decision.

A BRAVE CHOICE : THE PRODUCT AND THE TRANSPARANCY TOWARD THE CUSTOMER

Investing on the quality of the product has a return on the medium-long term.

The context of the current market is made of short term strategies, which consider be important only the marketing and advertisement investments. These strategies typical of the companies managed by managers has become a very widespread characteristic in the market of wall-hung gas boilers, in particular in the main market players.

Increase the reliability of the product means, for the companies, giving up to future incomes stemming from the sales of spare parts…

means antagonizing the world of maintenance and spare parts retailers.

This is why the marketing of the famous brands is based on the generic advertising (to the deceptive limits).

There is the trend of do not show the internal parts of the products, where there are many components made of plastic and low cost, which enable to ensure relevant returns on the after sale side with the favor of the maintenances firms who are their first promoter in the territory.

STEP, with big brave, has chosen to employ all its resources to the quality of the product.

This choice is appreciated by the “partners installers” who beyond sell and install the products, take charge also of the technical after sale service and have signed up with the producer a commitment to offer the “right price” to the customers both as regard the installation and the scheduled maintenances.

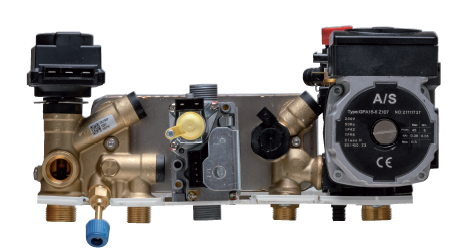

As mentioned above, the quality of the wall-hung gas boiler is given in large part by the quality of its components, a clear example is the Hydraulic block.